scratch test adhesion|scratch testing for coatings : trader Steinmann P.A., Tardy Y., Hintermann H.E.: Adhesion testing by the scratch test method: the influence of intrinsic and extrinsic parameters on the critical load. Thin Solid Films 154, 333–349 (1987) Google Scholar Valli J., Mäkelä U.: Applications of the scratch test method for coating adhesion assessment. Changelog. To view the changelog select the date in the navi.

{plog:ftitle_list}

25 de nov. de 2016 · We would like to show you a description here but the site won’t allow us.

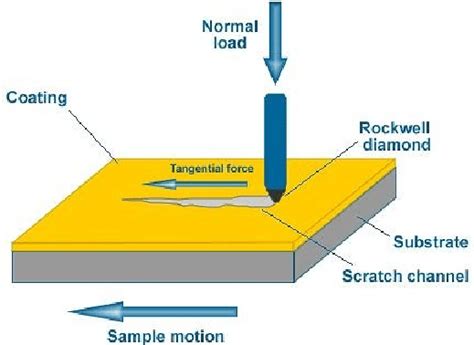

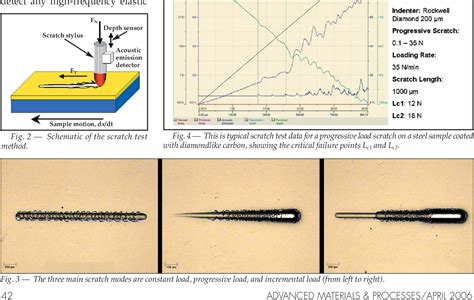

The scratch (or stylus) test is an adhesion test method that evolved from the scrape test. In the scratch test, a stylus is drawn over the film surface with increasing load. Under the point .There are three different procedures to assess the resistance of the coating to separate from the substrate and provide different adhesion analysis of the film: cross-hatch test, scrape adhesion test and a pull-off test. The scrape test . The new ASTM standard for scratch adhesion testing, ASTM C1624, covers the determination of the adhesion strength and failure modes of hard, thin ceramic coatings on metal or ceramic substrates. Scratch testers can be used for industrial quality control as well as scientific research. They should allow both lightly skilled operators and more experienced . Steinmann P.A., Tardy Y., Hintermann H.E.: Adhesion testing by the scratch test method: the influence of intrinsic and extrinsic parameters on the critical load. Thin Solid Films 154, 333–349 (1987) Google Scholar Valli J., Mäkelä U.: Applications of the scratch test method for coating adhesion assessment.

The scratch test has been used to assess thin coating adhesion for some time now. In this test a diamond indenter is drawn across the coated surface under an increasing load (either stepwise or continuous) until at some load, termed the critical load, L c a well-defined failure event occurs; if this failure event represents coating detachment then the critical load . Scratch testing is a more qualitative technique that can nonetheless allow interesting observations to be made on the cohesive bonds. Scratch testing is a widely used standardized method which can determine the adhesion strength of thin films (less than 20 μm thickness) to the substrate.

The Paint Adhesion Test Kit, (P.A.T.), contains all of the tools and materials needed, except for the multi-tooth cutter blade, for conducting adhesion tests on paints applied to a flat, uniform surface in accordance with ASTM Test Method D3359, method B and DIN Standard No. 53151. There are two kits available: The Cross Hatch Test Kit (12596) is great for any type of flat .At the Fraunhofer IST we use the following test methods, among others, to test the adhesion of layers: Scratch test (ASTM C1624, DIN V ENV 1071-3) In the scratch test, a diamond stylus is drawn across the surface with an increasing load. During this process, mechanical stresses are generated between the layer and the substrate which lead to .2 ISO 27307 – 2015 Thermal spraying — Evaluation of adhesion/cohesion of thermal sprayed ceramic coatings by transverse scratch testing 3 Lopez, Zambelli, Cohesion measurement of plasma sprayed ceramic coatings, Surface Modification Technologies (815-821), 1990Please call +1 (888) 287-5227 for further details about our paint scratch test and other coating testing services. Request Form " * * * * * * * * * * Coatings and Paints Testing. Coating Overview; Abrasion Testing . Coating Adhesion Testing; Coating Thickness Measurements ; Coatings; Color Gloss Testing; Crosshatch Adhesion Testing; DFT .

Scratch testing is a test method used to characterise the adhesion of surface coatings. The test involves drawing a hard tool (indenter) across the surface coating with increasing load, whilst using a calibrated load cell to record the measurements applied.8.2 Precision of Scratch test according to ASTM D3002. In the scratch hardness test, the scoring tool is a consumable. This wears out quickly, especially with hard layers. . DIN EN ISO 4624 Pull-off test for adhesion [8] EN ISO 16276-1 Pull-off testing [9] ASTM D4541 Pull-Off Strength of Coatings Using Portable Adhesion Testers Perry AJ (1983) Scratch adhesion testing of hard coatings. Thin Solid Films 107, 167-180. Qin F, Hu J, Chou YK, and Thom pson RG (2009) Delamination wear of nano-dia mond coated cutting tools in . Failure characteristics and adhesion evaluation of hydrogen-free amorphous carbon coatings (a-C and ta-C) were examined by scratch testing using different indenter tip radii. Based on previous work of some of the authors, this article provides an extended description of main failure modes occurring for brittle coatings, with respect to the ratio of indenter radius .

It is important to test the adhesion of the coating to the substrate (often glass or polymers) as well as scratch resistance. The Rtec Instruments 3D scratch tester enables you to perform fully automated scratch tests, which combine 3D confocal microscopy with interferometry to analyse scratches on transparent materials in high detail.

what is scratch testing

scratch testing process

5.3 The quantitative coating adhesion scratch test is a simple, practical, and rapid test. However, reliable and reproducible test results require careful control of the test system configuration and testing parameters, detailed analysis of the coating damage features, and appropriate characterization of the properties and morphology of the .Scrape Adhesion and Mar Testing Concept - The most widely used instrument for evaluating coatings for scratch adhesion and mar resistance is the Balanced Beam Tester. Stylus of the exact contour, both loop and needle, developed for the Balanced Beam Tester are now used in the S.A.M. Tester.

scratch test to determine adhesion properties of coatings // Ferrous Metallurgy. Bulletin of Scientific, Technical and Eco-nomic Information. 2020. Vol.76. No. 2, pp. 143-152 (In Russ.).

The scratch test for adhesion is reviewed as the only method currently available for testing thin, hard and well-adhering coatings such as TiC on steel or cemented carbide substrates. The critical load, mode of coating removal and acoustic signals are discussed. It is found that the combination of acoustic signal with microscopic observations .ATS offers a variety of ASTM coating adhesion testing capabilities to help clients optimize the functionality of their coating applications and avoid premature failure. Our testing services save clients money, providing them with the data necessary to pick the right coating and effectively protect their products, equipment, and infrastructure. In this paper, a literature review on scratch testing applied to coating/substrate systems is provided. Tribological contact mechanics, failure modes, factors affecting the scratch test results, adhesion measurements, friction effects as well as finite element modelling of the scratch test are discussed.

1. Introduction. Scratch testing is a commonly used method to assess the coating adhesion strength both in academic research and industrial fields [1, 2], due to its practical setups and quasi-quantitative measurements [3].The related mechanism is also deemed as a basic theory in tribology, for its importance in studying tribological contact mechanisms.The Scratch Test: Calibration, Verification and the Use of a Certified Reference Material N M Jennett and S Owen-Jones Measurement Good Practice Guide . who uses the scratch test as a measure of coating adhesion and who already has some knowledge of the use of scratch test instruments. The Guide is intended as a supplement to documents that . Testing the thin CrN and the TiN coatings with good adhesion to the polymeric ASA substrate with the modified scratch test failures in the composite of substrate and layer can be attained. The tests were run with bearing balls of 100Cr6 and linearly increasing loads from 0 to 50 N. Fig. 6 shows the average critical loads of the two samples and .

The adhesion strength of thin films is critical to the durability of micro and nanofabricated devices. However, current testing methods are imprecise and do not produce quantitative results . The aims of the present research are (1) to examine whether scratch testing can provide a suitable method for measuring the adhesion strength of thin calcium phosphate coatings applied to a compliant substrate, and, if it is a suitable method, (2) to use scratch testing to analyse changes in adhesion strength as a function of deposition . The scratch test has been used to assess the adhesion of thin hard coatings for some time now and is a useful tool for coating development or quality assurance.

Scratch Tests – run a fingernail or a sharp object across the print surface. Cross-Hatch/Scoring Tests – use a razor or an adhesion test kit to cut a pattern into the ink and using tape to see how much ink can be removed from the surface. Water Tests – submerge items into the water and then testing for reduced adhesion.

scratch testing of coated film

gas analyzer price

WEB11 de mai. de 2022 · Em coletiva de imprensa após o UFC 274, Charles Oliveira afirmou que sua próxima luta deve acontecer em novembro ou dezembro deste ano. "O timing é a mesma coisa do ano passado, novembro para dezembro. Deixa minha equipe ver com quem vamos lutar, com quem vamos fazer mais dinheiro. O legal é isso, de novembro .

scratch test adhesion|scratch testing for coatings